While navigating the world of printing technologies, you might have come across the term "UV printing." It's a hot topic in the industry, and you might want to understand its true value in printing operations.

In this guide, we'll explore what UV printing is, how it compares to conventional methods, and why it's becoming a preferred choice across various industries.

Conventional Printing vs. Ultraviolet Printing: How Does It Work?

Before we jump into the benefits of UV printing, let’s understand how it stacks up against traditional printing methods.

Conventional Printing

Traditional printing relies on heat or air to dry the ink. After the ink is applied to the substrate (the material being printed on), it must be dried, a process that can take time and may lead to smudging or ink absorption into the material. The result? A longer wait time and sometimes a less-than-perfect finish, especially on non-porous materials.

Ultraviolet (UV) Printing

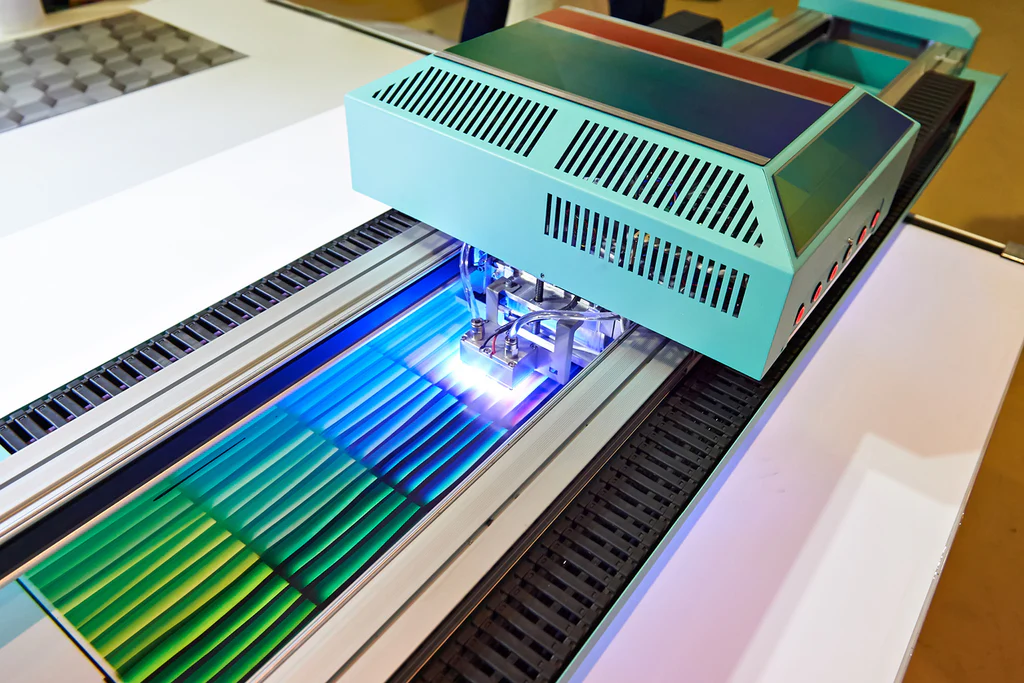

UV printing flips the script on traditional methods. Instead of relying on heat or air, UV printing uses ultraviolet light to cure or dry the ink instantly. As soon as the ink is printed on the substrate, it's exposed to UV light, which solidifies the ink on the spot. This quick-drying process allows for sharper, more vibrant prints on a wider range of materials, including glass, plastic, metal, and more.

Now that we've got a basic understanding, let's understand how UV printing works.

Ultra-Violet (UV) Printing – Procedure

UV printing might sound high-tech, but its procedure is quite straightforward, especially considering the sophisticated results it delivers.

- Ink Application: Just like in traditional printing, UV ink is applied to the substrate through a printer. However, the ink used in UV printing is different; it's formulated to react with ultraviolet light.

- UV Light Exposure: After the ink is applied, UV lamps that are built into the printer emit UV light onto the ink. This exposure causes a chemical reaction, which instantly dries and hardens the ink.

- Final Output: The result is a crisp, smudge-resistant, and highly durable print. Because the ink doesn't have time to soak into the substrate, the image remains sharp and vibrant, with no bleeding or spreading.

Now, let’s take a closer look at a variation of UV printing that’s making waves: LED UV printing.

LED UV Printing

LED UV printing is a type of UV printing that uses LED lamps instead of traditional mercury vapor lamps to cure the ink. It's an innovation that brings several additional benefits to the table:

- Energy Efficiency: LED UV lamps consume significantly less power than traditional UV lamps, making them a more eco-friendly option. They also generate less heat, reducing energy costs and the risk of damage to heat-sensitive substrates.

- Longer Lifespan: LED UV lamps have a much longer lifespan compared to mercury vapor lamps. This means fewer replacements and lower maintenance costs over time.

- Instant On/Off: Unlike traditional lamps that require time to warm up, LED UV lamps can be turned on and off instantly. This not only saves time but also further enhances energy efficiency.

LED UV printing is becoming increasingly popular in various industries due to these advantages. But where is UV printing making the most impact? Let’s explore its role in some key industries.

UV Printing in the Pharmaceutical Industry

The pharmaceutical industry has stringent requirements for packaging and labeling, and UV printing is stepping up to meet these demands.

- Security: UV printing can incorporate invisible inks and intricate designs that are difficult to replicate, helping to prevent counterfeiting—a significant concern in the pharmaceutical industry.

- Compliance: UV printing ensures that text and images on labels are crisp and clear, which is critical for complying with regulatory standards. This technology also supports the inclusion of braille or other tactile elements on packaging.

- Durability: Medications are often stored in varying environments, from refrigerated to room temperature. UV-printed labels are resistant to moisture, chemicals, and temperature changes; as a result, the vital information remains intact and legible throughout the product's life cycle.

UV Printing in the Food Packaging Industry

Food packaging needs to do more than just look good; it must also adhere to strict safety and regulatory standards. UV printing is making significant inroads in this area too.

- Safety: UV printing uses inks that are free from harmful solvents, making them safer for food packaging. This helps ensure that the packaging doesn’t contaminate the food it contains.

- Compliance: UV printing allows for the precise reproduction of barcodes, nutritional information, and expiration dates so that all packaging meets industry regulations.

- Aesthetics and Functionality: Food packaging often serves a dual purpose—it protects the food and markets it. UV printing can create eye-catching designs with vibrant colors that stand out on shelves. Plus, the durability of UV-printed packaging means it can withstand handling and transportation without losing its visual appeal.

Untold Benefits of UV Printing

UV printing offers a host of untold benefits that make it a versatile and powerful technology for businesses of all kinds. Let’s have a look.

Scope of Print Applications

One of the standout features of UV printing is its versatility. Unlike conventional printing, which is often limited to paper or cardboard, UV printing can be used on a wide range of substrates. This includes:

- Rigid Materials: Glass, metal, wood, and acrylic can all be printed with UV technology. This opens up possibilities for everything from signage to custom furniture.

- Flexible Materials: UV printing can also be applied to flexible materials like vinyl, fabric, and even leather. This is particularly useful in the fashion and textile industries, where custom designs and vibrant colors are in high demand.

Quicker than Conventional Printing

Because the ink dries almost instantly upon exposure to UV light, there’s no need to wait for prints to dry or worry about smudging. This not only speeds up the production process but also allows for faster turnaround times on orders.

For businesses, this means being able to meet tight deadlines without sacrificing quality. Whether you’re printing business cards, banners, or product labels, UV printing ensures that you can deliver on time every time.

Cost-Effective

While the initial investment in UV printing equipment might be higher than traditional printers, the long-term savings can be substantial.

- Reduced Waste: Since the ink dries immediately and doesn’t spread or bleed, there’s less wastage of materials. This leads to cost savings on both ink and substrates.

- Lower Energy Costs: Particularly with LED UV printing, the energy consumption is significantly lower than with traditional printing methods. Over time, this can result in considerable savings on energy bills.

- Durability: UV-printed products tend to last longer, which means less need for reprints due to wear and tear.

When you factor in these savings, it’s clear that UV printing offers excellent value for money, particularly for businesses with high-volume printing needs. If you're looking for equipment to get started, consider the Mimaki UCJV300 Series Print Cut. This Mimaki UV printer is powered by UV-LED technology for maximum efficiency.

Vibrant Finish

The finish achieved with UV printing is second to none. The instant drying process means that the ink sits on top of the substrate rather than being absorbed, resulting in sharper, more vibrant colors.

- High-Quality Output: Whether you’re printing fine details or bold, eye-catching designs, UV printing delivers high-definition results with consistent color accuracy.

- Glossy or Matte Finishes: UV printing can produce both glossy and matte finishes, adding another layer of customization to your prints. This flexibility allows businesses to create products that truly stand out.

This vibrant finish is not just about aesthetics—it also enhances the perceived value of printed materials, making them more appealing to customers and end-users. For those looking to maintain this high standard of quality, using a reliable Mimaki printhead can make all the difference in achieving consistent results.

The Bottom Line

UV printing is more than just a trend—it’s a transformative technology that offers unparalleled benefits across a wide range of industries. Its versatility, speed, cost-effectiveness, and vibrant finish make it a smart choice for businesses looking to stay ahead of the curve. And with advancements like LED UV printing, the technology is becoming even more accessible and efficient.

If you’re considering upgrading your printing capabilities, UV printing is well worth the investment. For more information on UV printing technology and how it can benefit your business, check out everything you need to know about UV printing and explore Mimaki Printers for top-of-the-line options.