Print shops across the country are discovering a game-changing addition to their equipment lineup: laser cutting and engraving systems. These precision tools are revolutionizing how commercial printers approach custom jobs, expand their service offerings, and boost their bottom line. From creating intricate signage to producing personalized promotional items, laser technology opens doors to new revenue streams while streamlining existing workflows.

The integration of laser cutters into print shop operations represents more than just adding another machine—it's about transforming your entire approach to customer service and production efficiency. As client demands shift toward more personalized, high-quality products, laser technology provides the precision and versatility needed to stay competitive in an evolving market.

What Are Laser Cutters and Engravers?

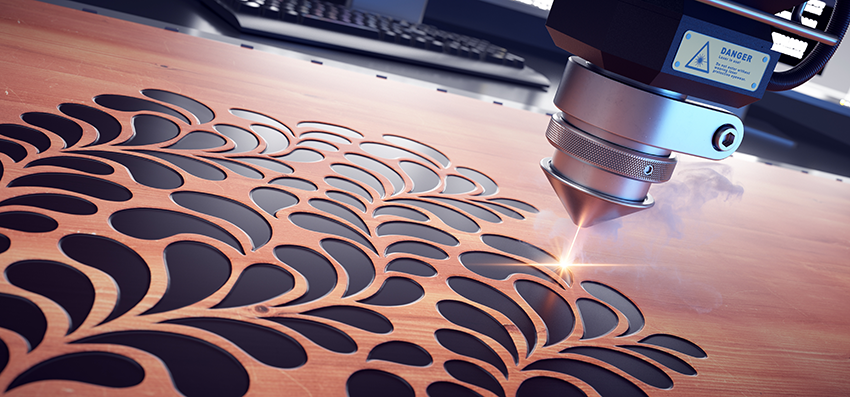

Laser cutters and engravers use focused laser beams to cut, engrave, or mark a wide variety of materials with exceptional precision. These systems operate by directing a high-powered laser through computer-controlled movements, allowing for intricate designs and clean cuts that would be impossible with traditional cutting methods.

Modern laser systems typically use CO2 or fiber laser sources. CO2 lasers excel at processing materials like acrylic, wood, paper, cardboard, textiles, and many plastics. Fiber lasers specialize in marking and engraving metals, including aluminum, stainless steel, brass, and precious metals. Some advanced systems combine both technologies, offering maximum material versatility.

The technology has evolved significantly, with today's systems featuring user-friendly interfaces that integrate seamlessly with existing design software. Most laser cutters operate much like large-format printers—you create your design in familiar programs like CorelDraw or Illustrator, then send the job directly to the laser system.

Benefits of Laser Cutters in Print Shops

Versatility in Materials

One of the most compelling advantages of laser technology is its ability to process an extensive range of materials. From traditional print substrates like paper and cardboard to specialty materials including acrylic, wood, leather, and textiles, laser systems handle diverse projects with consistent quality.

This material flexibility means your print shop can accept jobs that previously required outsourcing or declining. Acrylic cutting produces crystal-clear, flame-polished edges without additional finishing steps—a significant advantage over traditional routing methods that require secondary polishing operations.

Improved Precision and Quality

Laser systems deliver exceptional accuracy, typically within tenths of millimeters. This precision enables intricate contour cutting of printed materials, detailed engraving work, and complex geometric shapes that enhance the perceived value of finished products.

The contactless processing method eliminates wear on cutting tools and ensures consistent results across production runs. Unlike mechanical cutting systems, laser beams don't dull or require frequent replacement, maintaining consistent quality throughout extended production cycles.

Increased Efficiency and Speed

Modern laser systems significantly reduce production time through automated processes and advanced software integration. Print-and-cut workflows with optical recognition systems automatically align cutting paths to printed materials, compensating for printing variations and eliminating manual adjustments.

Large-format laser systems with features like Tandem Assist can increase productivity by up to 40%. While the laser processes materials in one zone, operators can unload finished pieces and reload new materials in an adjacent zone, minimizing idle time and maximizing throughput.

Cost Savings

The financial benefits of laser integration extend beyond increased revenue opportunities. Eliminating the need for cutting dies, routing bits, and other consumable tools reduces ongoing operational costs. The precision of laser cutting also minimizes material waste, particularly important when working with expensive substrates.

Labor costs decrease as laser systems require minimal manual intervention once jobs are set up. Automated cutting and engraving processes free up skilled operators for other value-added tasks, improving overall shop productivity.

How to Integrate Laser Cutters into Your Workflow

Choosing the Right Laser Cutter

Selecting the appropriate laser system requires careful consideration of your shop's specific needs. Work area size directly impacts productivity—larger systems accommodate more pieces per run and handle standard material formats more efficiently.

Laser power requirements depend on your primary applications. Engraving work typically requires 25-80 watts, while cutting applications or high-speed production benefit from systems exceeding 80 watts. Remember that a higher power provides greater application flexibility and faster processing speeds.

Consider future growth when making your selection. The modest cost difference between different work area sizes is often less than the potential revenue lost from jobs you can't accommodate with a smaller system.

Software and Training

Modern laser systems, like TROTEC integrate with existing design workflows through familiar software interfaces. Most systems include comprehensive material databases with pre-configured settings for common substrates, eliminating guesswork and reducing setup time.

Invest in proper training for your team. While laser systems are designed for ease of use, understanding optimal settings for different materials and applications maximizes both quality and efficiency. Many manufacturers offer comprehensive training programs covering everything from basic operation to advanced techniques.

Maintenance and Safety

Laser systems require regular maintenance to ensure optimal performance and safety. This includes cleaning optical components, replacing consumable parts, and maintaining proper ventilation systems.

Safety considerations are paramount when integrating laser technology. Choose systems with appropriate safety classifications and enclosed designs. Class 2 laser systems provide optimal safety while maintaining productivity. Proper ventilation systems remove dust and gases generated during processing, ensuring a safe working environment.

Examples of Enhanced Print Shop Services

Signage and Engraving

Laser technology excels at creating high-quality signage with professional finishing. Acrylic letters and logos can be cut with flame-polished edges in a single operation, eliminating secondary finishing steps. Contour cutting of printed materials creates eye-catching displays and point-of-purchase materials that command premium pricing.

Engraving applications range from simple nameplates to complex architectural signage. The precision and consistency of laser engraving produce professional results that enhance your shop's reputation and justify higher profit margins.

Custom Packaging

The growing demand for unique packaging solutions presents significant opportunities for print shops with laser capabilities. Custom cardboard displays, intricate folding designs, and personalized packaging elements help clients differentiate their products in competitive markets.

Laser cutting enables complex packaging designs that would be prohibitively expensive with traditional die-cutting methods. Small runs and prototypes become economically viable, opening doors to design-focused clients who value customization over volume pricing.

Personalized Promotional Items

Laser systems excel at creating personalized promotional products. From engraved awards and recognition items to custom keychains and branded accessories, these applications typically command higher margins than traditional print work.

The ability to quickly switch between different materials and designs makes laser systems ideal for promotional product work. Variable data processing allows mass customization, creating unique items for each recipient while maintaining efficient production throughput.

Maximizing Your Laser Investment

Success with laser technology requires more than just equipment installation. Develop relationships with suppliers who understand your applications and can provide technical support when needed. Consider partnering with manufacturers who offer comprehensive support packages including training, maintenance, and application development.

Marketing your new capabilities effectively helps maximize return on investment. Showcase the unique finishing options and precision capabilities that laser technology provides. Before-and-after examples demonstrate the quality improvements that justify premium pricing.

Track productivity improvements and cost savings to understand the full impact of your laser investment. Many shops find that improved efficiency in existing applications provides as much value as new revenue opportunities.

Laser cutting technology represents a transformative opportunity for print shops ready to expand their capabilities and increase profitability. The combination of precision, versatility, and efficiency makes laser systems valuable additions to modern printing operations. By carefully selecting the right equipment and properly integrating it into your workflow, laser technology can help your print shop stay competitive while opening new revenue streams.

Whether you're looking to improve existing services or explore entirely new markets, laser cutting technology provides the tools needed to take your print shop to the next level. The investment in quality equipment, proper training, and ongoing support pays dividends through increased efficiency, expanded capabilities, and enhanced customer satisfaction.

Visit us at Allprintheads.com and let us guide you in your next purchase of your Laser cutter.