Description

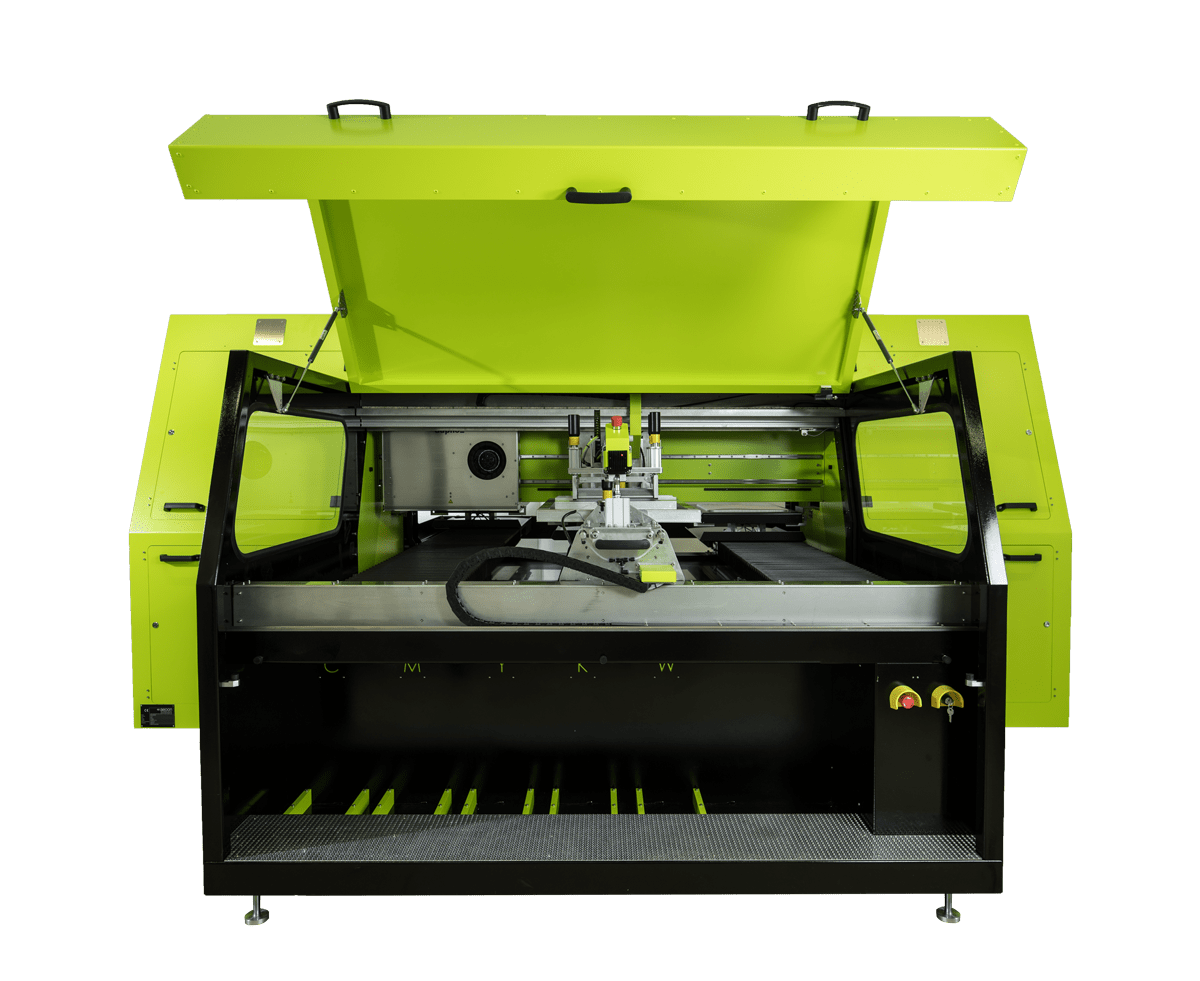

For the best of DTG and screen printing combined

The Kyo Hybrid Series is the first real combination of screen printing and digital textile printing, which combines the advantages of both. It is the ideal printer for high-volume production needs and offers a unique set of production flexibility.

The Kyo Hybrid Series can print on complex fabrics with or without pretreatment and can be used in three different production modes. In addition to standalone DTG printing or screen printing, a combination of both printing processes can also be easily integrated. This combination achieves significant savings in the consumption of white ink while delivering a premier hand feel.

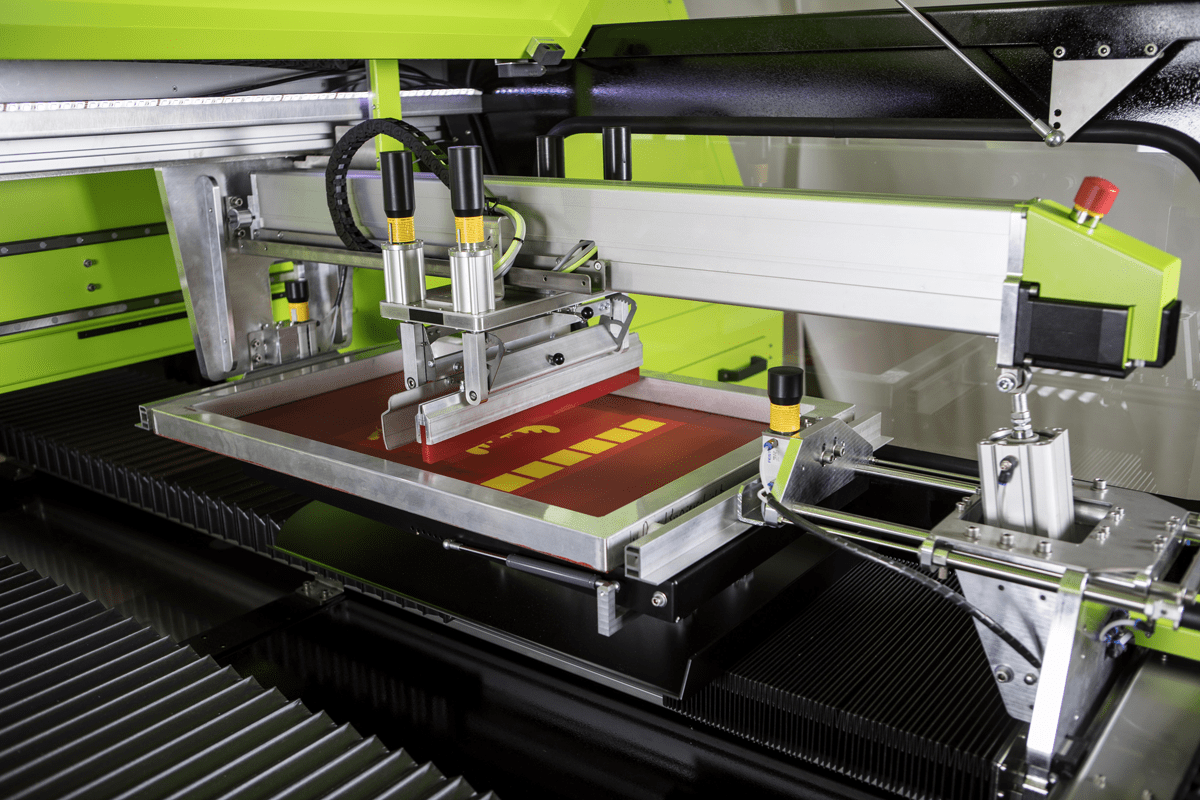

Our innovative KyoToScreen concept enables the most efficient workflow for the combination of screen printing and DTG printing. Easy and exact screen positioning, along with our one-step screen preparation, guarantee seamless integration of both print techniques.

With the Kyo Hybrid Series, you can cater to individual print jobs or long runs and offer the best of both worlds of digital and screen on a single printer. This Hybrid solution handles the registration issues with other Hybrid add-on solutions effortlessly.

Output DTG C8 – on a dark garment

Print size (40 x 20 cm / ~16 x 8 in)*

Depending on the performance of the operator, on the material and design.

Benefits:

- Screen printing and digital printing at the same time

- KTS – KyoToScreen

- App for screen setting (tablet)

- Screen adjustment up to 0.001 mm possible

- Save and recall screen printing settings easily via our in-house app

- Industrial print heads with a print resolution from 600 dpi up to 2400 dpi

- Integrated API interface

- Printing with or without pre-treatment

- Printing on complex fabrics possible

- Independent printing stations

- Cost-saving due to low consumption of white ink.

Charles Arapudaswamy, Senior Technical Manager, Arvind Mills Ltd

“We have purchased multiple DTG from aeoon for our factories around India. The last we opted for was their Hybrid model to produce bulk orders with even lower printing costs. We are delighted to have achieved that while maintaining the high-resolution print quality and ink ecological certifications, which is essential for our end-customers.

Technical specifications:

| Industrial printheads: | 8 or 12 |

| Print stations: | 2 or 3 |

| Color channels: | Double CMYK or Double CMYK|4W (Highlighter) |

| Max. Print size: | 50 x 70 cm; 19.7 x 27.6 in |

| Printable material: | Cotton, synthetics, mixed fibers, canvas, wood, leather, and more |

| Machine size: | 410 x 350 x 200 cm; 161.4 x 137.8 x 78.7 in |

| Machine weight: | 2600 kg; 5732 lb |

| Electrical connections: | 400/208 VAC, 50/60 Hz, 3 Ph, 16 A – max. Power: 7.5 kVA |

| Compressed air: | 7 bar – quality class 5 |

|

Environmental conditions: depending on the ink used |

Temperature: 22 – 28 °C, Humidity: 65 – 90 % |