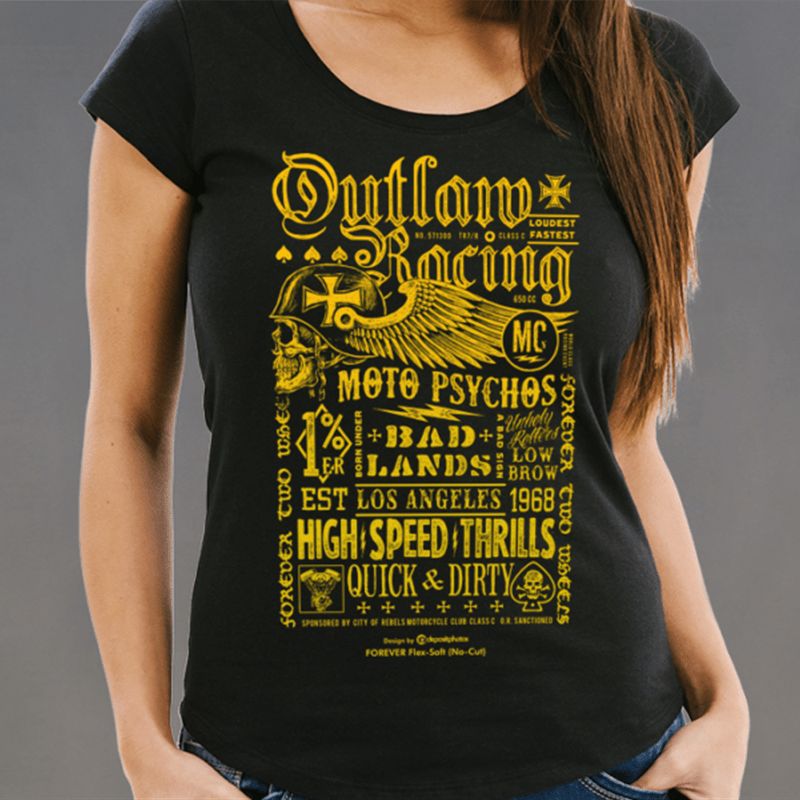

Laser Transfer Paper for Dark/Colored T-Shirts

SKU FS

Printing Instructions

- For OKI 831TS, OKI 920WT, and OKI 711WT: set the media to type setting to Film, Foil, or Transparency.

- For any other printer: Start with a Heavy setting and increase to Transparency or Label if you see streaks/smearing.

- Print the design on the matte side of the colored sheet (A foil sheet) in REVERSE or flip it horizontally. This can be done within the design program or printer’s settings (see your printer manual for more information).

- The paper should be fed into the copier/printer with the short dimension first, ideally using a straight path bypass tray.

- We recommend single-sheet feeding.

Application Instructions

Heat Press Only

This is a two-step process paper. Please follow directions accordingly!

Step 1

- Prepare heat press to 266-293 F°.

- Place 1-2 sheets of Regular Copy Paper on the lower platen to protect your silicone pad.

- Place the trimmed A-Foil in the middle of the lower platen (printed side facing up).

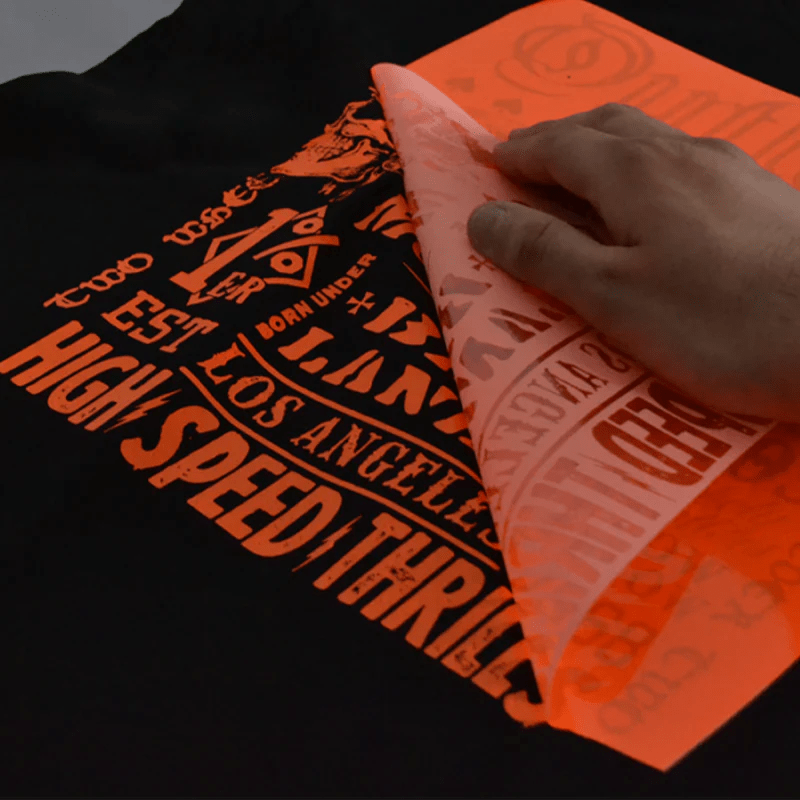

- Place the B-Paper LowTemp on the A-Foil (coated side facing down).

-

Cover all with 1-2 sheets of Regular Copy Paper.

NOTE: It is essential that the B-Paper LowTemp is slightly larger than the A-Foil to avoid mistakes. -

Press the A-Foil & B-Paper together for:

Ninety seconds for A4 paper size or 120 seconds for A3 paper size with medium pressure. - After opening the press, rub the B-Paper with a cloth for 5-10 seconds. Next, separate the B-Paper LowTemp from the A-Foil without lifting them from the lower plate in a slow, consistent motion.

Step 2

-

Place Forever FlexSoft A foil sheet with the printed image facedown onto the garment, and press transfer to the t-shirt using firm pressure using the following settings according to your substrate type:

Cotton: 275 F° - 310 F° | 30 seconds | medium pressure (40-60 psi)

Polyester: 275 F° | 30 seconds | medium pressure (40 psi)

Polypropylene: 212 F° | 20 seconds | light pressure (30 psi)

Blend Fabric: 266 F° | 30 seconds | medium pressure (40-60 psi)

Paper/Carton: 212 F° | 15 seconds | light pressure (20-30 psi)

Book Covers: 230 F° | 15 seconds | light pressure (20-30 psi) - After pressing, allow the transfer to cool fully, and peel the paper backing sheet.