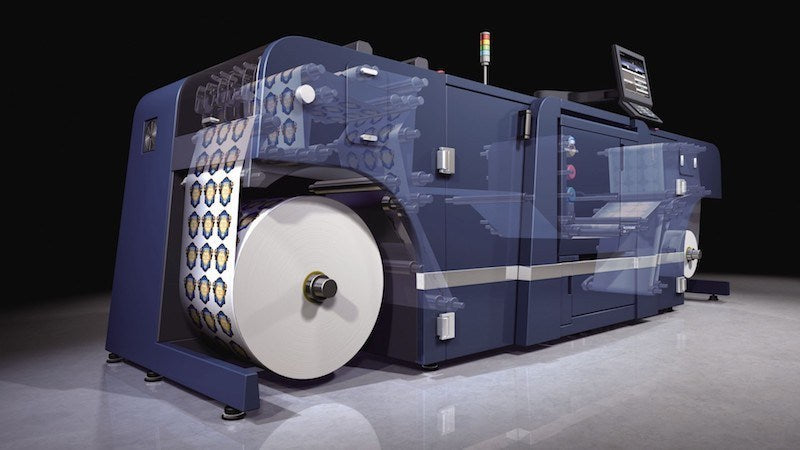

Konica Minolta has announced a new digital label press, the AccurioLabel 230, which is the third generation of this series, following from the original C71cf and AccurioLabel 190. Unusually, in this inkjet age, these are dry toner electrophotographic printers.

The most obvious improvement is to the maximum speed, up from 18.9 mpm to 23.4mpm but there’s a lot more going on under the hood. This printer looks the same on the outside as the outgoing AccurioLabel 190 but Konica Minolta has used a completely different print engine. As with the older machine, Konica Minolta has taken the imaging engine from one of its sheetfed production presses and adapted this for continuous feed. In this case Konica Minolta has used the engine from its AccurioPress 3080, which also means that the 230 gains the newer toner. This engine gives it 1200 x 1200 dpi resolution, printing in CMYK.

However, Edoardo Cotichini, team manager for Konica Minolta’s Industrial Printing division, is keen to stress that Konica Minolta has put in a lot of work to integrate the print engine with the winders, saying there are different sensors and pointing out that the start and stop nature of continuous feeding means there are different signals going back and forth and a need to control the web tension.

Konica Minolta has continued its partnership with the Danish company Grafisk Maskinfabrik, or GM, which supplies the winders. Cotichini says: “We worked with GM and there’s a lot of back and forth so that development of this machine took quite a while, around one and a half years.”

Cotichini adds that Konica Minolta picked GM was because it wanted a partner that can also support the press with a range of finishing equipment, including die cutting, foiling and varnishing.

The new press can handle the same range of substrates as the older model, namely non-tack paper, tack paper, tack coated paper, tack synthetic paper, tack PP and tack PET. Cotichini points out that being a dry toner machine this press can print direct to different papers without requiring any sort of priming. However, whereas the old model would slow down for certain types of substrates, the 230 can print at its top speed on all materials, meaning that some users will see an even more significant increase in speed. It takes media from 250 to 330mm wide, and from 81 to 256gsm, though it does slow down to 18.9mpm on substrates that are 177gsm or heavier.

In addition, Konica Minolta has also done away with the need to print a colour bar on the edge of the web when printing jobs that are longer than 500m, which takes up 2mm on the substrate with the 190 press. But the 230 benefits from the approach developed for the 3080, where the different colours are aligned and read on the transfer belt to check the density.

Another important difference is that the new press can now print 1000 linear metres without needing to pause. Part of the legacy of using a print engine from a sheetfed press is that the AccurioLabel series do need to stop to recalibrate the colour every so often, and this leaves a white gap where the printing has paused. But pushing this to 1000 linear metres all but eliminates this issue for most users, as Cotichini explains: “Our break even point against a flexo press is 700 metres because it’s more profitable to use a flexo press above that, unless you are using variable data.” He says that over the last few years flexo presses have become much easier to run so they have reduced set-up times and costs, mainly to compete against the likes of HP Indigo.

Cotichini adds: “About 85 percent of those installations are label converters so they have at least one or more flexo presses and sometimes another digital press.” He says that the majority of customers use the AccurioLabel presses for short run work, which is typically 200-700 metres but can be as low as 50 linear metres. He says that there are also customers with more than one AccurioLabel press and that some customers are printing up to 70,000 metres per month.

He adds: “We have some cases where our machine is sitting side-by-side with an Indigo, because it’s easier to operate and there’s less set-up time with ours. So the Indigo operator is running our press as well and if there’s less than 250m then they have automated flows to send those jobs to our machine, because it’s more profitable to do the short runs on our press.”

Edoardo Cotichini, product manager for Konica Minolta’s AccurioLabel presses.

Other improvements include support for JDF and JMF commands, and shorter warm-up times down to half a minute when idling. There’s also an optional overprinting kit, which includes an additional eye mark sensor that allows the 230 to print full colour digital images on to pre-coated media with accurate registration.

There are two versions of the 230, depending on geography. In Europe, the US and Africa, the winders come GM, but in China and India Konica Minolta has instead opted to use winders from the Chinese firm Brotec. This is mainly because these markets are more price-sensitive but Cotichini points out that Brotec also has a bigger presence in these countries, meaning that it can offer the necessary support, including finishing.

The starting price for the AccurioLabel 230 is €180,000. Most customers also pay a click charge that covers consumables as well as servicing but Konica Minolta also offers a reduced charge for the servicing, allowing customers to buy the consumables as needed.

I’ve little doubt that Konica Minolta will do very well with this press, if only because it already has over 368 label presses installed worldwide, which suggests that converters accept Konica Minolta’s assessment of the market – namely that the opportunity for digital printing lies in very short run lengths, midway between an entry-level label printer and a flexo press. As such, the AccurioLabel machines offer the sort of image quality and reliability that we would expect from a production machine, at a relatively low price and running cost. It’s not a fast machine, but ease of use and short set-up times are the key to high productivity and thus more important for short runs.

Konica Minolta says that it has already started shipping this model though it’s due to be officially unveiled at the Label Expo show in Brussels in September. You can find more information on Konica Minolta’s approach to the label market here.

1 comment

Sangare Aboubacar

Bonjour Monsieur je suis Monsieur sangare Directeur général a Pifcolor une entreprise de fabrication d emballages et étiquettes. Nous aimerions avoir plus informations sur vos machines de production d étiquettes prix et performance merci